Organic, climate positive wastewater treatment

This plant will also allow, after being treated with this technology, to be reused for irrigation areas, which can be public parks. This work has important economic benefits. It strikes me that this may be one of the plants with the cheapest operating costs in the country.

April 2011

It is the most efficient plant in the Mexican Republic. The cost of treating a cubic meter is in the order of 20 cents, it is an atypical case. The technology used there, the small space it needs, the results it produces, is the best plant in the Mexican Republic… This is not Ney Gonzales saying it, it is the National Water Commission saying it.

August 2011

The modernization of Irrigation District 01 is a leading project of this type. In Mexico, it has the intention to increase the efficiency in the use of resources in irrigation units, through the technological development of the information systems and the training of the producers. The modernization consists of the substitution of the water transportation system in canals for the irrigation of 6100 hectares of plots of land, an important part of the national program for the sustainable use of water in agriculture.

June 2008

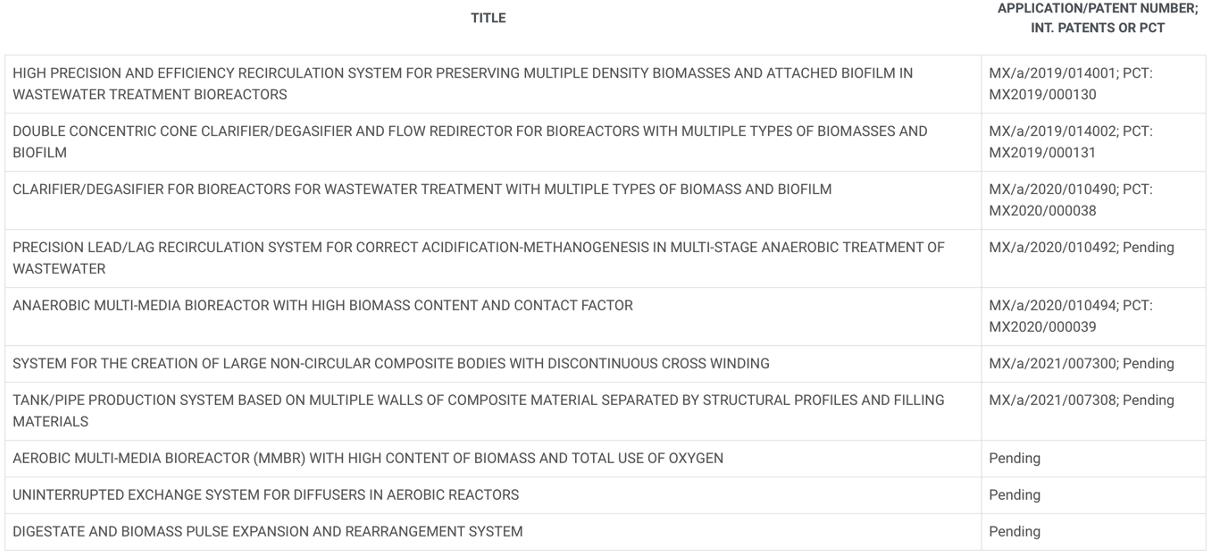

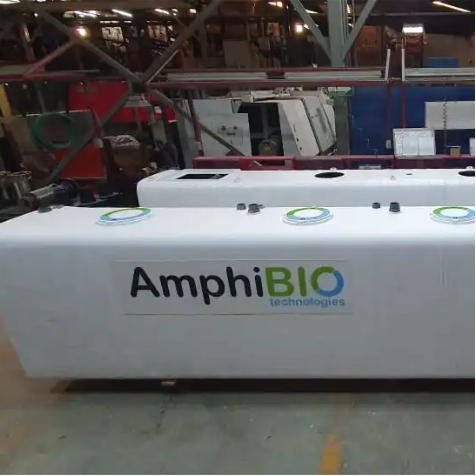

Flows from 1 to 450 LPS (per train), loads up to 100,000 mg/l COD The Multi-Media BioReactors (MMBRs) were the logical successions of CBBRs when larger volumes or higher load influents needed to be treated. They are the latest generation process units for the biological treatment of water. They are characterized for packing large quantities of granular, diffuse, and fixed biomass under a controlled pH and temperature environment and in state-of-the-art fluidized reactors of very particular designs and properties.

To achieve this, extensive rheology and Computational Fluid Dynamics (CFD) simulations were required, along with physical testing of scale and full-size models. As a result, we came up with what we believe is the most compact and energy-efficient biological process to treat wastewater to a high-quality effluent in the world[1]. So efficient that, with enough organic load present, the rectors generate more energy in the anaerobic stages in the form of usable biogas that, when converted to electrical power, is more than what is used in the anoxic, aerobic, and even disinfection stages of the process.

Currently, 42 reactors are in construction for influents ranging from 4,000 to 20,000 mg/l of COD with and without nutrient removal, and there are projects with influents of 40,000 mg/l in tequila vinasses and up to 100,000 mg/l for corn processing industries.

Flows from 2 to 400 m3/day, loads up to 1,500 mg/l COD The Combined Baffled BioReactor (CBBR) was developed building on the strengths of the Combined BioReactor and designed to overcome some of its limitations. It is a full composite, portable, compact biological unit that typically incorporates 7 to 10 stages of any combination of anaerobic, anoxic, and aerobic processes according to the treatment needs. After the biological stages, tube settler clarifiers and UV disinfection are typically integrated. The synergy achieved in this unit capitalizes on the advantages that each has to offer and can process a wide range of influents to a high-level standard with a minimal footprint and energy consumption.

The Combined BioReactor (CBR) is an advanced deep digester that serves as a primary sedimentation tank with integrated anaerobic, pre-anoxic, and aerobic processes for both sludge and water in a single, carefully stratified receptacle.

CBRs were always paired with Rotating Biological Contactors (RBCs), of which we designed and manufactured the largest in the world. CBR+RBCs combined in what for a long time was the most energy-efficient mechanical process for a high-quality effluent we found in the world (not considering biogas utilization).However, they required a larger initial investment than conventional systems and were susceptible to mechanical problems when they weren’t appropriately operated. For these reasons, and mostly because of our newly developed CBBR and MMBR technologies, almost all new projects have been resolved with the latter.

Over 50 plants with more than 140 processing trains and systems have been built with this technology since 2009.Consistently they were the most efficient plants in the states in which they were installed.When properly maintained, they produce excellent water quality at an outstanding cost; however, partly because of the initial cost and maintenance reasons mentioned above, and mostly because of newer developed technologies, almost all new projects have been resolved with CBBR and MMBR technology.